What is Cleaning in Place (CIP)?

CCIP means Clean in Place. It describes automatic cleaning without the disassembly of production equipment on site, for example in the beverage and food industry. CIP systems can be used to remove production-related deposits and contamination from tanks as well as piping systems, among other areas in which contaminants may occur. In this process, the areas and objects to be cleaned are connected in a circuit with a CIP system. The cleaning sequence is individually adapted to meet the cleaning requirements of the object in question and to the degree of contamination.

Why is CIP cleaning important?

Production -surfaces in contact with the product may retain products-residues which can serve as growth medium for microorganisms. If harmful microorganisms are not regularly removed by cleaning and disinfection processes in your plant, product safety and/or product quality will suffer. Depending on the contamination, you may be faced with shortened minimum shelf lives or even product recalls.

To prevent this, efficient cleaning and decontamination of all plant components is of utmost importance. However, complex geometries such as piping, valves, internals in tanks or heat exchangers in closed systems are not accessible at all or only with difficulty. Automated CIP allows you to save time and money by eliminating costly and manual cleaning procedures while improving hygiene in your systems. This applies equally to open systems such as storage tanks. Successful cleaning is an essential aspect in guaranteeing a high level of microbiological safety for your products and thus contributes to quality assurance.

What are the advantages of Clean in Place?

Nowadays, CIP systems are an indispensable part of modern manufacturing processes, not only in the beverage but also in food industries. The main advantage of the CIP technology is the omission of disassembly of your installation to clean and disinfect product-leading parts. It is therefore also suitable for cleaning difficult-to-access parts of your system where manual cleaning methods are no longer effective or feasible. With the aid of built-in nozzles or spray balls, even large-volume system parts such as tanks can be cleaned without complete flooding.

The advantages of the CIP process

The CIP process is a fully automated process and should be perfectly adapted to your production facility. As a result, a consistently high, reproducible cleaning quality is achieved with minimal use of time and resources – this drastically reduces cleaning costs. Depending on the cleaning tasks and the circulation volume of the cleaning circuit, it may make sense to reuse the cleaning media – referred to as backstacking. As it is individually tailored to your requirements, you can optimize the consumption of cleaning media and wastewater volumes, making a meaningful contribution to protecting the environment.

The ever-increasing energy costs make CIP systems even more interesting for you. With its energy-efficient mode of operation, the process simultaneously reduces the energy consumption of both the process and the cleaning system. Hence you can achieve very good cleaning results and optimized energy consumption for your plant simply by relying on the automated processes and precisely adjustable parameters such as temperature, flow rate and duration of action of the cleaning medium.

Advantages at a glance

- Increased product safety due to reproducible cleaning results

- Increased employee safety compared to manual cleaning processes

- Savings in valuable resources such as water, time, energy and chemicals

- Reduction of cleaning costs (lower wastewater costs, reduced process costs, shorter cycle times)

Your challenge

As a manufacturer it is key to prevent contamination and harmful microorganisms that can result from remaining product residues. Increasingly stringent laws and hygiene regulations require detailed documentation of cleanliness of your equipment and cleaning processes. Naturally, you only want to interrupt your production process as short as absolutely necessary for cleaning and must avoid downtimes as far as possible in order to operate economically.

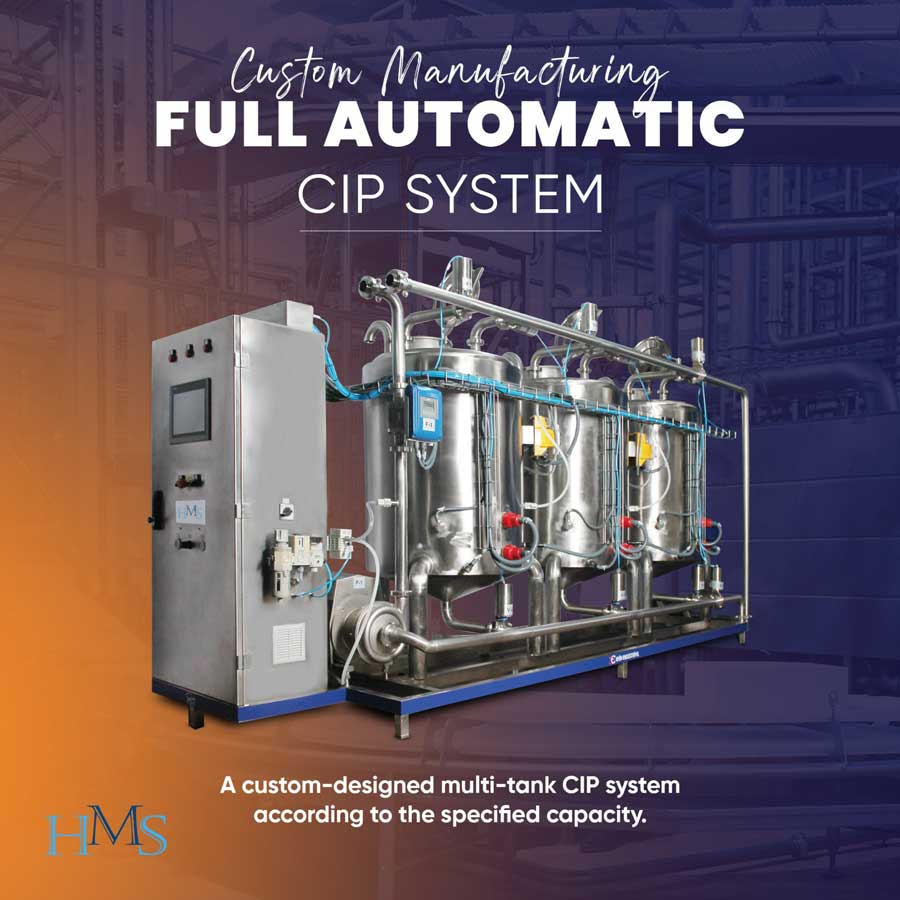

Our solution

Automated, localized internal cleaning and disinfection for your filling lines.

Process hygiene is therefore a major issue, especially in the beverage and food industry. Industry experts have long been concerned with topics such as reproducible cleaning, resource savings, and food safety.

HMSmachines's automatic CIP cleaning can bypass cumbersome and expensive manual cleaning and improve the hygiene of your systems. Our CIP products are also suitable for open systems (e.g. storage tanks) to increase efficiency. Successful cleaning improves the microbiological safety of your products and is an important component of your quality assurance.

Of course, we will examine each application individually and determine the cleaning options with your field of use in mind. Usually, mainly piping systems, tanks, vessels, heat exchangers, reactors and special tanks are cleaned with in-place cleaning processes.

We will be happy to advise you on your individual needs and help you optimize your parameters.

We are not in a direct partnership with chemical distributors, allowing us to deliver cleaning technology that can be used with a variety of chemicals. The choice is always yours.